UV-curable resins are an ideal material for 3D printing parts quickly and accurately. Toagosei America works with uniquely high-performing products that bring impressive benefits to 3D printing applications. The products we supply allow photopolymer formulators to achieve effective end results.

As a global manufacturer of commodities and specialty chemicals, Toagosei America has the technology to solve 3D printing resin challenges. For over 70 years, we’ve brought innovation to the chemical industry, with reliable, high-quality solutions. Our team can help you identify the best UV-curable resin for your application, and even develop new raw materials to fit your needs.

Types of UV Curable Resin for the 3D Printing Industry

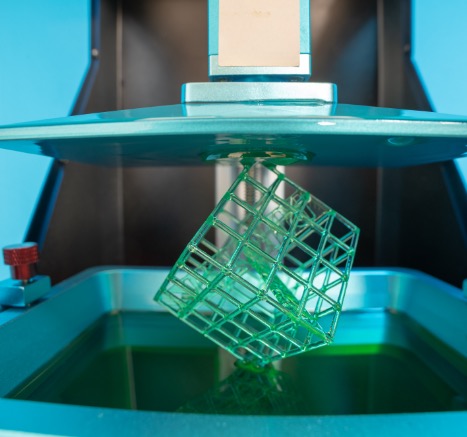

Resins used in 3D printing are liquid photopolymers. When exposed to a UV light source, they change their physical properties, hardening and strengthening into a smooth-finished object that cannot be remelted. Toagosei America offers two types of UV-curable resin:

- Oxetane Monomers (Aron Oxetane®): Classified as a cationic curable resin, Aron Oxetane is used in 3D printers due to its high reactivity and low viscosity. It is typically mixed with glycidyl ether epoxy resin to create photopolymers that have very little shrinkage when exposed to UV light.

- Acrylate monomers (Aronix®): This type of monomer is mixed with oligomers, photoinitiators and additives to improve UV curability, heat resistance and toughness of the Photopolymers. In addition there are monomers that contain high volumes of bio-based materials.

Both types of resin feature faster curing time that facilitates increased production efficiency. They are also easily customizable to the needs of a specific use and can be altered to feature improved surface hardness, toughness, adhesiveness, or viscosity.

3D Printing Applications of UV Curable Resin

The versatility of UV-curable resins allows them to be valuable in numerous types of 3D printing applications. Some of the most common uses for UV-curable resin include:

- Functional prototypes

- Consumer products

- Castings

- Thermoforming tools

- Generally low friction and low-wear mechanical parts

- Tooling

UV curable resins from Toagosei America can be used to custom-engineer to enable specific performance capabilities, such using M-140 to increase toughness, M-923 to increase Tg or M-5700 to increase flexibility. Other monomers improve impact resistance, castability, and more. Depending on the specific formulation, resins are used to cost-effectively create jewelry design castings, medical devices such as hearing aids, orthodontic devices, surgical guides, automotive parts and much more.

Benefits of using Toagosei America for UV Curable Resin

Choosing Toagosei America for UV-curable resin ensures your 3D-printed components feature an improved surface finish and limited shrinkage during the curing process, allowing you to create more realistic parts. When UV-curable resins are used in 3D printing applications, they create components with the highest possible level of detail.

UV-curable resins feature a viscosity that facilitates faster printing speeds and brings the added benefit of no VOC emissions. Resins from Toagosei America also ensure no volume loss occurs during the curing process. Other benefits of UV resins include:

- Environmentally friendly, with low energy requirements

- Fast dry times prevent dust and other airborne impurities from contaminating the print surface

- No solvents are needed for viscosity reduction, resulting in no volume loss or VOC emissions

- Achieves a high gloss surface immediately, without the need for further steps, or can be formulated to meet other aesthetic goals

3D Printing Solutions from Toagosei America

UV-curable resins from Toagosei America bring new levels of innovation to the field of 3D printing. Our versatile product line facilitates highly accurate and speedily produced 3D-printed components. To learn more about our product offerings contact our team today.