Industrial adhesives are inorganic and organic materials that provide permanent industrial-grade adhesion for electronics, construction components, medical devices, and automobile components, among many other uses and applications.

Finding the suitable adhesives that best fit your application needs is essential. Industrial adhesives can provide security, longevity, and damage resistance against elements, especially in industrial settings.

When it comes to industrial adhesives, stick with Toagosei America. We are a global manufacturing company specializing in industrial-grade adhesion technology, and we offer a wide range of adhesives to suit almost all kinds of applications.

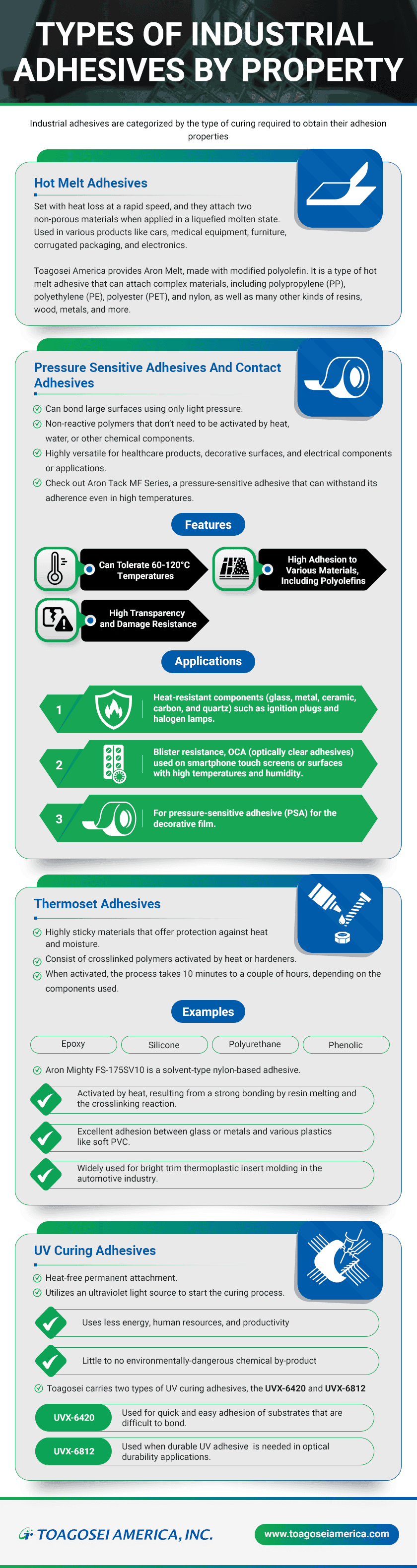

Types Of Industrial Adhesives By Property

Industrial adhesives are categorized by the type of curing required to obtain their adhesion properties – hot melt, pressure sensitive and contact, thermoset, and UV curing adhesives.

Hot Melt Adhesives

Hot melt adhesives are set with heat loss at a rapid speed, and they attach two non-porous materials when applied in a liquefied molten state. Because of these qualities, hot melt adhesives are used in various products like cars, medical equipment, furniture, corrugated packaging, and electronics.

Toagosei America provides Aron Melt, made with modified polyolefin. It is a type of hot melt adhesive that can attach complex materials, including polypropylene (PP), polyethylene (PE), polyester (PET), and nylon, as well as many other kinds of resins, wood, metals, and more.

Pressure Sensitive Adhesives And Contact Adhesives

Pressure-sensitive and contact adhesives can bond large surfaces using only light pressure. In addition, these types of adhesives are non-reactive polymers that don’t need to be activated by heat, water, or other chemical components. Pressure-sensitive and contact adhesives are highly versatile for healthcare products, decorative surfaces, and electrical components or applications.

At Toagosei, America, we carry Aron Tack MF Series, a pressure-sensitive adhesive that can withstand its adherence even in high temperatures. Aron Tack MF Series can tolerate 60-120°C temperatures and has high adhesion to various materials, including polyolefins. It also features high transparency and damage resistance.

We recommend the Aron Tack MF Series for the following usages:

- For heat-resistant components (glass, metal, ceramic, carbon, and quartz) such as ignition plugs and halogen lamps

- For blister resistance, OCA (optically clear adhesives) used on smartphone touch screens or surfaces with high temperatures and humidity

- For pressure-sensitive adhesive (PSA) for the decorative film.

Thermoset Adhesives

Thermoset adhesives are highly sticky materials that offer protection against heat and moisture. These types of adhesives consist of crosslinked polymers activated by heat or hardeners. When activated, the process takes 10 minutes to a couple of hours, depending on the components used. Examples of thermoset adhesives are epoxy, silicone, polyurethane, and phenolic.

Toagosei America produces thermoset adhesives made from the latest innovations in industrial adhesives. Our Aron Mighty FS-175SV10 is a solvent-type nylon-based adhesive. Aron Mighty is activated by heat, resulting from a strong bonding by resin melting and the crosslinking reaction. This product performs excellent adhesion between glass or metals and various plastics like soft PVC. It is widely used for bright trim thermoplastic insert molding in the automotive industry.

UV Curing Adhesives

For a heat-free permanent attachment, we recommend UV-curing adhesives. It uses an ultraviolet light source to start the curing process, using less energy, human resources, and productivity while having little to no environmentally-dangerous chemical byproduct.

Toagosei carries two types of UV curing adhesives, the UVX-6420 and UVX-6812. We recommend the UVX-6420 for quick and easy adhesions of substrates that are difficult to bond. If you need a durable UV adhesive for optical durability applications, try UVX-6812. You may observe minor yellowing due to UV or heat.

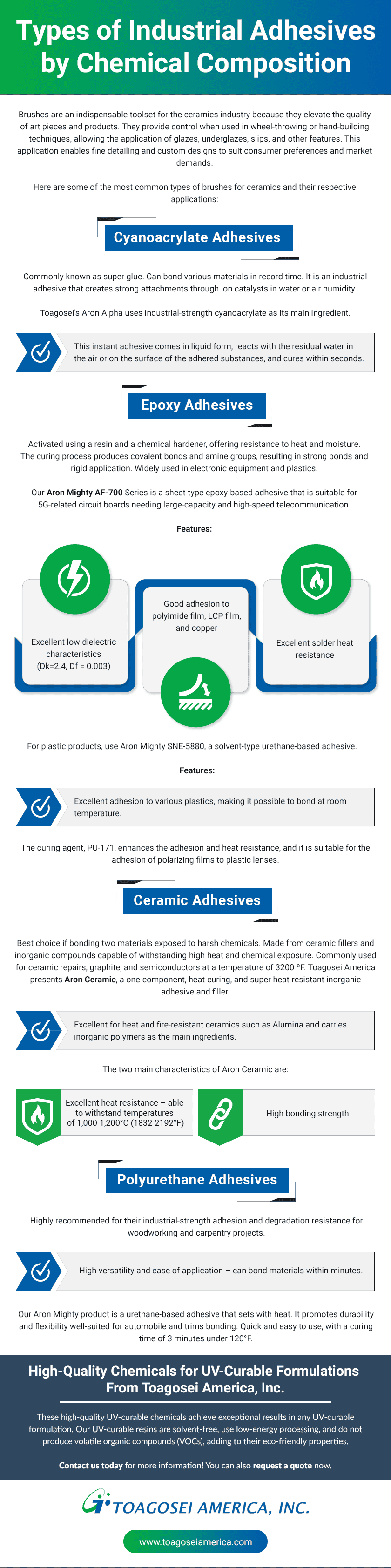

Types of Industrial Adhesives by Chemical Composition

Another categorization of industrial adhesives is their chemical composition. These include cyanoacrylate, epoxy-based, urethane-based, ceramic, and polyurethane adhesives.

Cyanoacrylate Adhesives

More commonly known as super glue, cyanoacrylate adhesives can bond various materials in record time. It is an industrial adhesive that creates strong attachments through ion catalysts in water or air humidity.

Toagosei’s Aron Alpha uses industrial-strength cyanoacrylate as its main ingredient. This instant adhesive comes in liquid form, reacts with the residual water in the air or on the surface of the adhered substances, and cures within seconds.

Epoxy Adhesives

Epoxy adhesives are activated using a resin and a chemical hardener, offering resistance to heat and moisture. The curing process produces covalent bonds and amine groups, resulting in strong bonds and rigid application. Epoxy adhesives are widely used in electronic equipment and plastics.

Our Aron Mighty AF-700 Series is a sheet-type epoxy-based adhesive. It has excellent low dielectric characteristics (Dk=2.4, Df = 0.003) and good adhesion to polyimide film, LCP film, and copper. It also has excellent solder heat resistance. Therefore, it is suitable for 5G-related circuit boards needing large-capacity and high-speed telecommunication, like antennas of mobile phones and millimeter-wave radar of autonomous cars.

For plastic products, use Aron Mighty SNE-5880, a solvent-type urethane-based adhesive. This product performs excellent adhesion to various plastics, making it possible to bond at room temperature. The curing agent, PU-171, enhances the adhesion and heat resistance, and it is suitable for the adhesion of polarizing films to plastic lenses.

Ceramic Adhesives

Ceramic adhesives are your best bet if bonding two materials exposed to harsh chemicals. They are made from ceramic fillers and inorganic compounds capable of withstanding high heat and chemical exposure. This industrial adhesive is commonly used for ceramic repairs, graphite, and semiconductors at a temperature of 3200 ºF.

Toagosei America presents Aron Ceramic, a one-component, heat-curing, and super heat-resistant inorganic adhesive and filler. It is excellent for heat and fire-resistant ceramics such as Alumina and carries inorganic polymers as the main ingredients.

The two main characteristics of Aron Ceramic are:

- Excellent heat resistance – able to withstand temperatures of 1,000-1,200°C (1832-2192°F)

- High bonding strength – even at high temperatures, metals and ceramics show a very high bonding strength.

Polyurethane Adhesives

Polyurethane adhesives are highly recommended for their industrial-strength adhesion and degradation resistance for woodworking and carpentry projects. In addition, it is a thermoset adhesive that can bond materials within minutes, providing high versatility and ease of application.

Our Aron Mighty product is a urethane-based adhesive that sets with heat. It promotes durability and flexibility well-suited for automobile and trims bonding. It’s also quick and easy to use, with a curing time of 3 minutes under 120°F.

Stick With Toagosei For Unique And Functional Industrial Adhesive And Chemical Technology

Toagosei America’s industrial adhesive line will meet any of your project’s needs. We pride ourselves as a top pioneer in the global manufacturing of adhesive technology. With our qualifications in functional adhesive and chemical technology, we are highly capable of and devoted to satisfying manufacturing specifications and requirements. Contact us now for quotes and inquiries, and our team of experts will gladly help you.