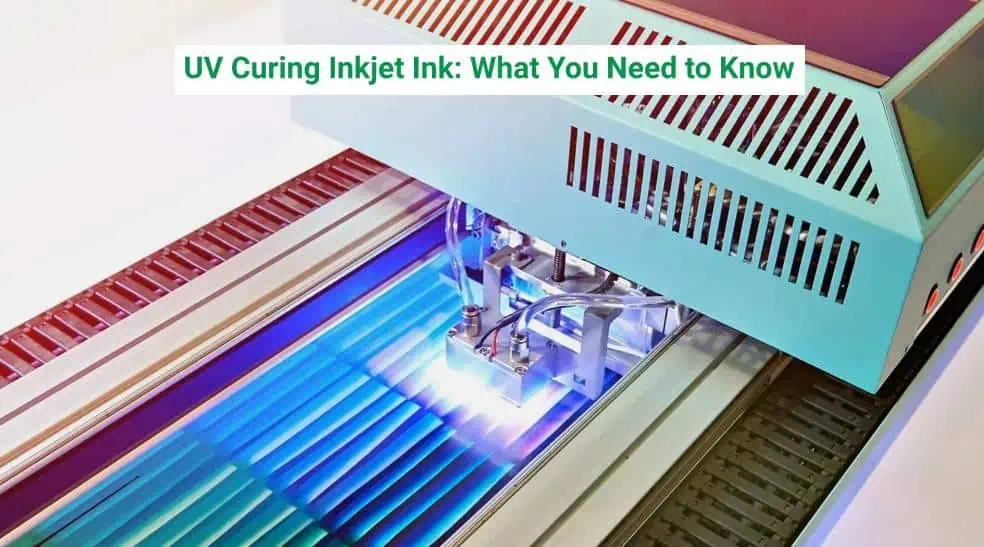

Ultraviolet (UV) curing inkjet ink relies on an environmentally-friendly photochemical process to dry ink instantly after printing. This means that you can print on nearly any non-absorbing material, including metal, wood, glass, vinyl, and more. Unlike certain other types of printing, UV curable ink is cured on the surface of the substrate so the substrate can be nonporous, resulting in no smudging and no need for costly pre coatings. In this blog, we’ll discuss the process and key benefits of UV curing inkjet ink to help you determine if it’s the best option for your next printing project.

What Are UV Curing Inkjet Inks?

Rather than relying on absorption into substrates for drying, UV curing inkjet inks are formulated to remain in liquid form until they are cured via exposure to UV and LED lights as well as electron beam(EB) This initiates an instantaneous photochemical reaction in which the ink components are cross-linked, creating a durable polymer.

UV curing inks contain four primary components: monomers, oligomers, photointiators and additives such as pigments. These compounds are what allow the photochemical reaction to occur upon exposure to UV light. When the ink makes contact with UV light, the photoinitiators form radicals that begin the polymerization of the monomers. These inks contain no solvents and derive their color from pigment dispersion.

UV Curing Process

UV curable inkjet inks require efficient, consistent, and complete curing to ensure optimal functionality, durability, aesthetic appeal, and surface properties for printed products. As previously mentioned, UV curing is a photochemical process that relies on highly intense ultraviolet light to quickly cure or “dry” inks.

UV curing inks are formulated with oligomers and monomers combined with a small amount of photoinitiators and other additives. Once exposed to UV energy, the ink instantly hardens, allowing the printed product to quickly move on to the next processing step.

Benefits of UV Inkjet Inks

UV curing inks provide a range of benefits that make them ideal for various applications. The major advantages of using UV curing inks include:

- High-quality properties such as excellent bond and adhesive strength, scratch resistance, and chemical resistance

- Relies on less energy and solvent-free technology for a more environmentally friendly solution

- Higher production capacity and speed

- High image and color quality

- Durability

- Superior reliability and consistency

- Product is immediately ready for the next process step

- Compatible with 2D and 3D component geometries

- No VOC emissions

- Higher yield rates

UV Curable Solutions From Toagosei America Inc.

UV curing inkjet inks offer an eco-friendly, instant printing solution that creates a strong, durable print on a wide variety of substrates. As a global manufacturer of functional adhesive and chemical technologies, Toagosei America, Inc. delivers a range of UV curable solutions for industries such as 3D printing, UV adhesives, UV inks and inkjets, UV coating, electronics, and automotive. We offer various types of monomers designed to improve the performance of UV curing inkjet ink, including:

- M-313. This monomer increases the durability of cured products and can enhance the elastic modulus of UV adhesives.

- M-5700. This monomer increases the flexibility of a cured product and offers fast UV curability. When combined with M-313, it can enhance the overall adhesion of UV curing inkjet ink.

- M-930. This monomer offers a low viscosity tri-functional acrylate with biobased content and increases the chemical resistance of the print.

In addition to M-313 and M-5700, we offer a wide range of other monomers that can increase scratch resistance, improve optical durability, provide hydrolysis resistance, and more. For more information about how our UV curable resins can meet your UV ink needs, contact us today.